CO₂ Laser Machine Troubleshooting Guide: Tube to Optics

CO₂ Laser Machine Basics

What’s Inside a CO₂ Laser Machine

A CO₂ laser machine is built from a few key parts that work together to make and guide laser energy. The star of the show is the laser tube, filled with a mix of gases (mostly carbon dioxide, nitrogen, and helium). When you hit it with electricity, the gas lights up with a laser beam. Mirrors and lenses point and sharpen that beam onto whatever you’re working on. The power supply keeps the tube fed with energy. Cooling systems stop things from getting too toasty during long runs.

You use a control panel to dial in stuff like power, speed, or how deep you want to cut. This lets you tweak the machine for all sorts of jobs. Safety bits, like emergency stop buttons and guards, keep everyone out of harm’s way.

Where CO₂ Lasers Get the Job Done

CO₂ lasers are like Swiss Army knives, handy in tons of fields because they can cut, engrave, or mark all kinds of stuff. It kicks off when electricity jolts the gas in the tube, making a tight beam of light. That beam gets steered by optics right to your workpiece.

In doctor’s offices, they’re used for things like smoothing out skin or fading acne scars, peeling off just the top layer without touching what’s nearby. In workshops, they slice through metal, plastic, or wood with crazy precision. They’re also big in beauty treatments, like blasting away tattoos or unwanted hair by zeroing in on specific colors or roots.

Their do-it-all vibe makes CO₂ lasers a go-to treatment for medical and shop work.

Typical CO₂ Laser Machine Hiccups

When the Laser Tube Acts Up

The laser tube is a big player, and when it’s off, things go south fast. A weaker beam is usually the first hint of trouble. You might spot patchy cuts or engravings. If the tube’s got cracks or leaks, it’s likely banged up.

Cloudy or weird-colored gas inside the tube means it’s either dirty or running low. Let these slide, and the whole machine could quit on you.

Power Supply Woes

The power supply’s job is to keep the laser tube powered up steady. Old parts or loose wires can make the power jumpy. You’ll notice the beam acting wonky or the machine cutting out mid-task.

If the power supply gets too hot or overloaded, it might just shut off. Giving it a regular once-over keeps it happy and saves you from bigger headaches.

Alignment and Calibration Glitches

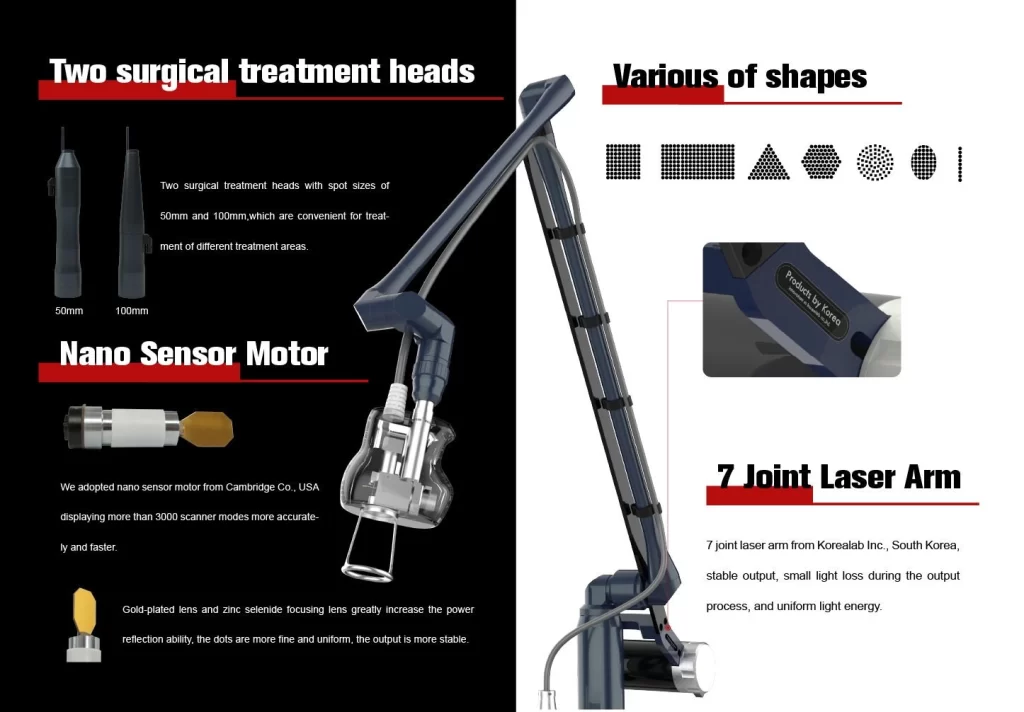

Your mirrors and lenses need to be lined up just right to aim the beam where it’s supposed to go. If they’re off, cuts can look twisted or engravings uneven. Messed-up calibration can also screw up how deep or wide your cuts are.

Running the machine a lot can nudge things out of place. A quick re-tune now and then keeps it sharp.

Fixing the Laser Tube

Figuring Out Tube Troubles

Spotting Gas Leaks

A leaky laser tube messes with pressure and gas mix, tanking performance. Check for cracks or dents on the tube. Brush some soapy water on spots you’re worried about while the machine’s on low power. Bubbles mean you’ve got a leak.

Catch leaks early to avoid a bigger mess. For little ones, special glue can hold things together until you get a proper fix.

Handling Power Flickers

If the power’s bouncing around, it’s likely the tube or wiring acting up. Start by poking around the power supply connections for anything loose or rusty.

If the wires look solid but the power’s still wobbly, use a multimeter to check voltage while the machine’s doing different jobs. Big ups and downs might mean something’s busted inside and needs swapping out.

Swapping or Patching a Bad Tube

Replacing a dud laser tube takes some careful steps:

- Pull all the wires hooked to the tube.

- Undo the clips or screws holding it down.

- Pop in a new tube that matches the old one’s specs.

- Plug the wires back in, following the maker’s guide.

- Check alignment and calibration before firing it up again.

For small cracks letting gas slip out, grab a repair kit with glue made for glass tubes. It’s a temporary band-aid. Regular check-ups make tubes last longer and keep surprises low.

Tackling Power Supply Problems

Looking at Wires and Voltage

Catching Power Supply Overheating

Overheating’s a common power supply pain, causing shutdowns or sluggish work. Peek at the cooling setup first. Check that fans are spinning and vents are clear. Blocked vents or busted fans trap heat.

Grab a thermal camera or infrared thermometer to spot any hot zones. If it’s too warm, clean the cooling bits and replace anything shot. Staying on top of upkeep stops these issues cold.

Stopping Circuit Breaker Flips

If your breaker keeps tripping, you’re likely dealing with too much juice or a short circuit. Look over the wires for wear, rust, or loose ends. Tighten anything wiggly and clean rusty bits with the right stuff.

Use a clamp meter to check how much current the machine’s pulling. If it’s overloading the breaker, think about getting a beefier one, but only if it’s safe and matches the maker’s rules. Also, check parts like capacitors for damage that might be sucking extra power.

Keeping Power Smooth

Steady power keeps your beam strong and cuts clean. Voltage swings can throw everything off. A UPS or voltage stabilizer can block surges or dips.

Test the power supply’s output with a multimeter and compare it to the maker’s specs. If things still act up with a stabilizer, get a tech to dig deeper.

Sorting Out CO₂ Laser Optics

Catching Optical Slip-Ups

Checking Mirrors and Lenses

Mirrors and lenses guide and focus the beam. Scratches, cracks, or dirt can mess it up and weaken the laser. Give each one a good look under bright light.

Wipe off dirt with a soft, lint-free cloth and a cleaner made for laser optics. If something’s damaged, swap it out—fixes won’t cut it.

Tweaking the Beam Path

Out-of-whack optics make for crooked cuts or blotchy engravings. Use a laser pointer or alignment tool to follow the beam’s path. Nudge the mirrors little by little till it’s spot-on.

Double-check that brackets are tight so nothing shifts while you’re working. Vibrations and wear mean you’ll need to tweak it regularly.

Cleaning and Caring for Optics

Clearing Off Lens Dust

Dust on lenses scatters light and dims your beam. Blow it off with compressed air, then wipe gently with a lens-safe cloth and cleaner. Skip anything rough that might scratch.

For sticky gunk like oil, dab a cotton swab with a solvent the maker says is okay.

Handling Optics Right

Messy handling can dirty or break optics. Slip on gloves to keep your skin’s oils off. Stash extra parts in protective cases, away from sun or damp spots.

Don’t lean too hard when adjusting optics—it can throw them off or crack them. Steady care keeps them going strong and cuts down on downtime.

Nubway makes killer CO₂ laser machine service built for precision and all kinds of work. Our stuff’s in over 120 countries, trusted by salons, clinics, and shops. With CE, FDA, and ISO13485 stamps, our machines are safe, solid, and ready to roll.

Nubway’s got 24/7 help, training, and custom setups. Choose Nubway for top tech and awesome support.

FAQ

Q: How can I tell if my laser tube is failing?

A: A failing tube might show weaker power output, uneven cuts, or visible cracks. Cloudy or discolored gas inside suggests contamination or gas depletion.

Q: How do I check for gas leaks in the laser tube?

A: Inspect the tube for cracks or damage. Brush soapy water on suspected areas while running the machine at low power. Bubbles indicate a leak.

Q: Can I fix a leaky laser tube myself?

A: For small leaks, you can use a repair kit with glass-safe glue as a temporary fix. For major leaks or cracks, replace the tube or get professional help.

Q: How do I replace a faulty laser tube?

A: Disconnect the wires, remove the mounting brackets, install a new tube matching the original specs, reconnect the wires per the manufacturer’s guide, and test alignment/calibration before use.